Manufacturing Excellence

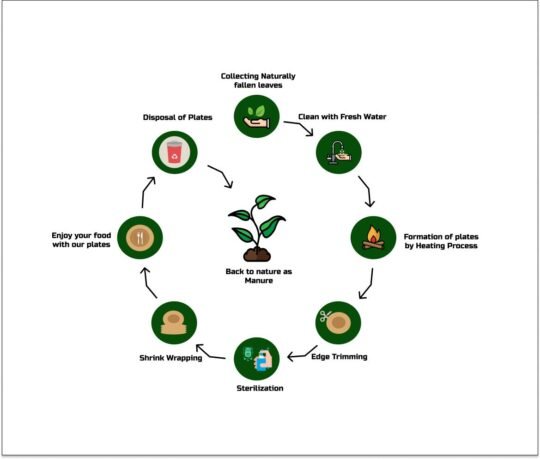

Manufacturing areca leaf plates involves several steps. Here's a detailed step-by-step process:

- Procurement of Areca Palm Leaves: Areca palm leaves are primarily sourced from regions where areca palm trees are abundant and In India, Karnataka has the largest number of Areca palm tree cultivation. Farmers collect the naturally fallen sheaths and separate them from the leaf. After the separation, the farmers send the sheaths to the manufacturer for further process.

- Cleaning with Fresh water, Sorting and Soaking: The collected leaves are thoroughly cleaned in Fresh Water by Pressure washer/ by hand to remove any dirt, dust, or impurities. They are then sorted based on size, thickness, and quality .The sorted leaves are soaked in water for a certain period of time, typically a few hours. This process helps in making the leaves pliable and easier to shape without causing breakage.

- Formation Of Plates by Heat Press: After soaking, the leaves are placed in a hydraulic press or mold designed specifically for shaping them into Different Sizes according to your needs. The hydraulic press applies pressure to mold the leaves into the desired shape and size.

- Edge Trimming : The edges are trimmed to remove any uneven or excess portions, resulting in uniform edges and also undergo additional finishing processes to smoothen the surface and enhance their appearance.

- U.V Sterilization: The Formed plates undergo U.V sterilization process to ensure hygiene and safety , the plates are placed in a U.V sterilization chamber to eliminate any potential pathogens or contaminates present on the plates.

- Quality Control: Before packaging, the plates undergo thorough quality control checks to ensure that they meet the required standards in terms of size, shape, strength, and overall quality.

- Packaging: The finalized areca leaf plates are carefully packaged in sets or stacks, ready for distribution and sale. Packaging is usually done using eco-friendly materials to maintain the sustainability of the product.

- Recycling of Areca Waste: After pressing the plates areca leaves sheath waste will be left. The waste can be used into making food stock for cattle or composted , because of its chemical composition, the sheath is comparable with paddy straw and has some minerals in high values as copper, calcium and sulphur.

Manufacturing Process

Manufacturing Excellence in Areca Leaf Plates & Palm Leaf Bowls at SriAgro

At SriAgro, we believe that great products begin with great processes. Every plate and bowl we produce is a result of innovation, sustainability, and precision. With our state-of-the-art facility, we transform naturally fallen Areca palm leaf sheaths into premium-quality areca leaf plates and palm leaf bowls. Our production system emphasizes hygiene, eco-consciousness, and zero waste, ensuring that every piece of eco-friendly tableware is safe, durable, and beautifully crafted.

From sourcing raw materials to delivering finished products, SriAgro stands as a trusted palm leaf tableware manufacturer exporter, creating natural tableware that blends tradition with modern technology.

How Areca Leaf Plates & Bowls Are Made – SriAgro’s Manufacturing Process

The journey of our eco-friendly plates and bowls begins with nature. Our raw material is not harvested by cutting or harming trees; instead, it comes from naturally fallen Areca palm leaves, collected from farms in southern India, particularly Karnataka. This ensures that every piece of tableware is sustainable palm leaf plates – no trees harmed.

Design & Technology Highlights

- Hydraulic heat press moulds for precision shaping

- UV sterilization chambers to maintain hygiene standards

- Soaking and sorting for uniform thickness and crack resistance

- Rigorous quality control — strength, leak-proof, and aesthetic testing

- These innovations allow us to deliver eco disposable dinnerware for weddings, catering services, events, and everyday household use.

Eco-Friendly Tableware & Natural Tableware by SriAgro

Chemical Free Production

From cleaning to pressing, we avoid chemicals, waxes, or synthetic coatings. Each product is simply natural, making them safe, hygienic, and eco-conscious.

Eco and Biodegradable

Our eco-friendly tableware is fully biodegradable. When discarded, they break down naturally without polluting soil or water. You can even learn how to dispose palm leaf tableware naturally through composting.

Durable and Practical

Unlike flimsy paper or plastic plates, our disposable plates without plastic are strong, leak-proof, and heat-resistant. They are safe for ovens, microwaves, and freezers, perfect for sustainable tableware for events and family use.

Supporting Local Farmers

By sourcing only from naturally fallen leaves in southern India, SriAgro supports rural communities, promotes responsible farming, and boosts the regional economy.

Our Range of Manufacturing Excellence

Areca Leaf Plates

Our areca leaf plates come in round, square, rectangle, and different shaped areca leaf plates – heart shape, boat shape, and more. They are versatile and stylish, perfect for organic compostable plates for catering services or everyday dining.

Palm Leaf Bowls

Our palm leaf bowls are compostable, leak-proof, and microwave safe. Ideal for serving soups, gravies, desserts, and salads, they’re popular among caterers looking for areca leaf bowls wholesale.

Palm Leaf Bowls

Our palm leaf bowls are compostable, leak-proof, and microwave safe. Ideal for serving soups, gravies, desserts, and salads, they’re popular among caterers looking for areca leaf bowls wholesale.

Event & Catering Solutions

From eco disposable dinnerware for weddings to themed parties, our sustainable palm leaf plates deliver elegance while being eco-conscious.Our natural organic tableware is especially popular among event planners across India and abroad.

The SriAgro Commitment

- SriAgro goes beyond manufacturing — we are building a culture of sustainability. Every palm leaf dinnerware product reflects our values of quality, eco-responsibility, rural women empowerment and community support.

- Eco-friendly plates and bowls with zero chemicals

- Microwave safe areca leaf plates for convenience

- Compostable palm leaf bowls that are microwave safe

- Organic compostable plates for catering services

- Sustainable palm leaf plates – no trees harmed

- Global reach as a palm leaf tableware manufacturer exporter

- By choosing SriAgro, you embrace eco-friendly living while supporting rural livelihoods and reducing global plastic dependency.

FAQs on Areca Leaf Plate Manufacturing

At SriAgro, we use only naturally fallen areca palm leaf sheaths collected from local farms. No trees are ever cut down in the process. Our careful selection ensures that only clean, fungus-free, and sturdy leaves are chosen. This ethical sourcing not only protects the environment but also supports rural farmers, making our raw material truly 100% natural, sustainable, and eco-friendly.

Yes, the entire process at SriAgro is 100% natural and free from chemicals, coatings, or synthetic polish. The leaves are simply washed with water, sun-dried, and later sterilized with heat and UV light. We never use wax, dyes, or harmful finishes.

The manufacturing process involves heat press moulding, where the selected palm leaf sheaths are soaked to remove impurities and soften them. They are then placed into moulding machines that apply controlled heat and pressure to form different shapes and sizes — from round plates to heart, boat, and square designs.

Hygiene is our top priority. Every plate undergoes UV sterilization, high-heat pressing, and strict quality inspections to ensure safety and durability. The use of modern sterilization techniques ensures plates are free from bacteria, fungus, or dust particles. Additionally, our facility follows stringent food-grade hygiene standards, making SriAgro plates suitable for homes, hotels, catering services, and large-scale events.

At SriAgro, nothing goes to waste. Leftover leaf pieces and trimmings are collected and composted naturally contributing to a zero-waste production model. This approach minimizes the environmental footprint and supports a circular economy.

At SriAgro, we use only naturally fallen areca palm leaf sheaths collected from local farms. No trees are ever cut down in the process. Our careful selection ensures that only clean, fungus-free, and sturdy leaves are chosen. This ethical sourcing not only protects the environment but also supports rural farmers, making our raw material truly 100% natural, sustainable, and eco-friendly.

Yes, the entire process at SriAgro is 100% natural and free from chemicals, coatings, or synthetic polish. The leaves are simply washed with water, sun-dried, and later sterilized with heat and UV light. We never use wax, dyes, or harmful finishes.

The manufacturing process involves heat press moulding, where the selected palm leaf sheaths are soaked to remove impurities and soften them. They are then placed into moulding machines that apply controlled heat and pressure to form different shapes and sizes — from round plates to heart, boat, and square designs.

Hygiene is our top priority. Every plate undergoes UV sterilization, high-heat pressing, and strict quality inspections to ensure safety and durability. The use of modern sterilization techniques ensures plates are free from bacteria, fungus, or dust particles. Additionally, our facility follows stringent food-grade hygiene standards, making SriAgro plates suitable for homes, hotels, catering services, and large-scale events.

At SriAgro, nothing goes to waste. Leftover leaf pieces and trimmings are collected and composted naturally contributing to a zero-waste production model. This approach minimizes the environmental footprint and supports a circular economy.